JD Edwards Configurator – Is That Even a Word? What Is It?

Configurator – Is That Even a Word? What is it?

Mike Archer | Sr. Functional Consultant

Configurator was totally made up!

According to the APICS dictionary:

A “Configuration” is “An arrangement of components as specified to produce an assembly.”

A “Configurator” is “A software system that creates, uses, and maintains product models that allow complete definition of all possible product options and variations with a minimum of data entries.”

The JD Edwards Configurator automates the selection and configuration of highly complex products by providing fully integrated front-end sales and quote entry, with back-end fulfillment operations and manufacturing systems. Configured Order Entry guides users in the creation of customized end-item product through product definition (features and options), rules, and calculations.

If this sounds complex, it is because this tool does a lot of heavy lifting to manage your complex operations.

The truth is, Configurators were born out of necessity (think “Lean” initiatives) to reduce complexity and waste in processes. Also, to vastly reduce the amount of data and data maintenance which, in turn, all conspire to reduce the overall time it takes from order to the delivery and improve product accuracy. This all must get done as quickly and as accurately as possible.

How is this accomplished?

Well, first we should think about what the above challenges are with a little more detail.

Data & Maintenance = Bills of Materials, Routings, Prices.

When quotes or orders are taken from customers, custom products are usually handed over to engineering and marketing to set up the details that establish the BOM’s, Routings, and Prices.

This can be very time consuming and cumbersome and put a lot of pressure on the users who are responsible for that part of their process. This can sometimes cause a lot of stress and, eh, human error…

Time from Order to Delivery:

- Customer sends order information, and it is taken by customer service or outside sales.

- Customer Service notifies and shares the order with engineering if there is no part number already (usually a part number with meaning in its characters to identify what makes it unique).

- The engineering department finds a similar BOM and usually copies and tweaks it to include/exclude details that will satisfy the new order. This establishes what the cost is for the customized product. Now, the price can be determined and set up. [Sometimes, engineering may have to tell Customer Service that the custom order isn’t a valid combination of options, which means more time working with the customer to see if they would accept other options - and this all adds to the overall time to get their product].

- Now that BOM, Routing, and Price is set up as a distinct item, Customer Service can now enter a Quote or an Order.

This all takes a lot of time and effort and must be coordinated every day with accuracy so that customers will be satisfied with the services you provide. We all know what it is like to not get what we ordered…

The JD Edwards Configurator gives feedback to the customer service user immediately upon making the selections on the Configurator Entry form and that can be shared with the customer while they are on the phone. Once the order is placed, a work order is created and will include configured parts list and routing. The sales order already has the price and cost rolled up which accurately reflects the configuration.

JD Edwards Configurator will give you the tools to establish the parts, price, and overall cost at the fingertips of Customer Service even without saving the order. The user can change options on the fly and see how the cost and price changes before they even place the order. This is because the configured item (product model) will be established ahead of time with all the rules needed for the product. There are also ‘validation’ rules that can be set up which help guide the user to enter orders that are valid. No more ability to select incompatible options and must wait for engineering to let Customer Service know if it is right or wrong.

But how (you say)?

I just told you… With rules!!!

There are rules that govern what parts you use for certain option selections, what steps in the manufacturing process changes for different selections that affect labor, and how the price changes for different selections.

Chances are, if you’re a business that’s make-to-order and you have lots of features and options for a product model and you create a lot of BOM’s and Routes, then you may need a Configurator. It would also be true that you already have these rules, but they are just in the minds of several people.

What does JD Edwards Configurator look like? Can we really see price & cost update while entering orders? What else can we see?

Calm down, I am getting to that…

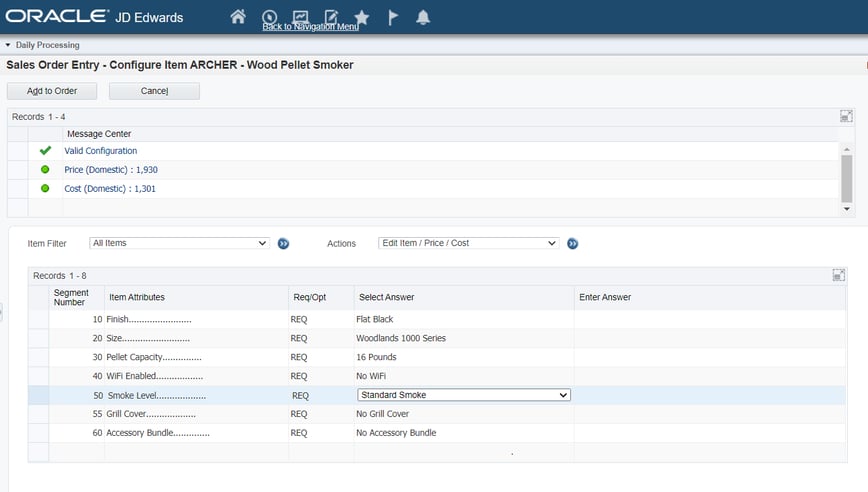

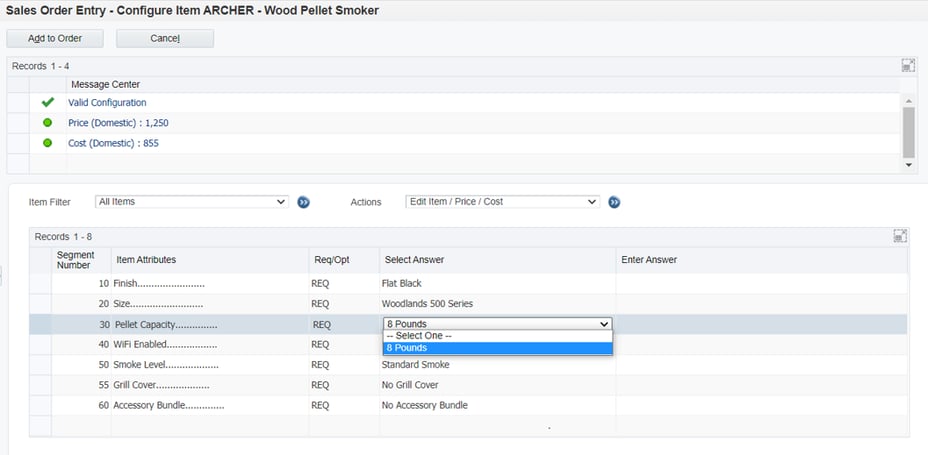

Let us have a look at entering a JDE Configured order for a new Pellet Smoker Grill for the back patio.

From Sales Order Entry, the user enters ‘ARCHER’ as the part number, and the system launches Configured Order Entry (above) so that they can enter all the desired selections.

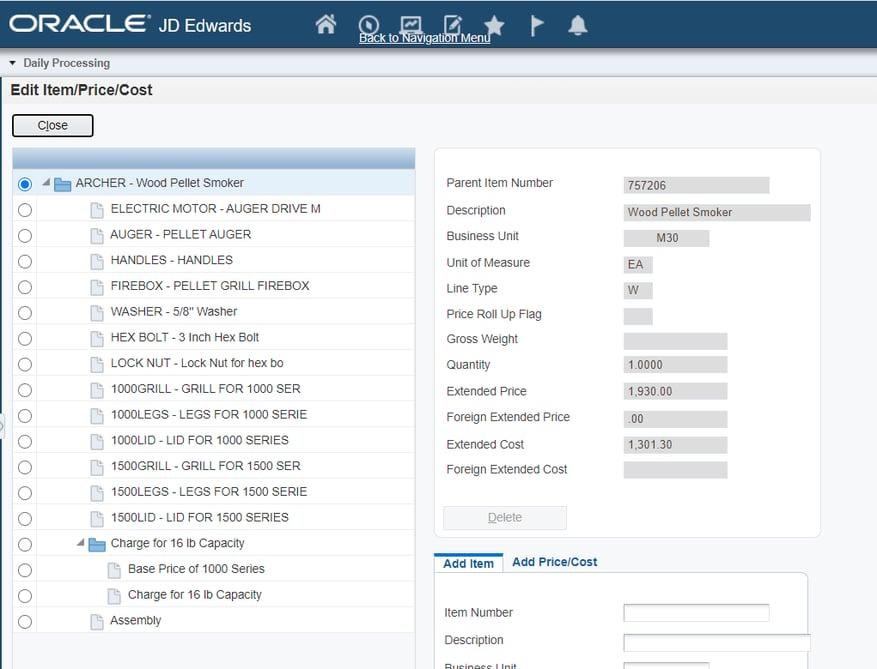

Notice that the selections made result in a Price and Cost. If desired, the Customer Service user can also see what the parts and labor are that make up the cost, and what charges make up the price:

The user can click on each detail and see how it individually contributes to the cost and/or price.

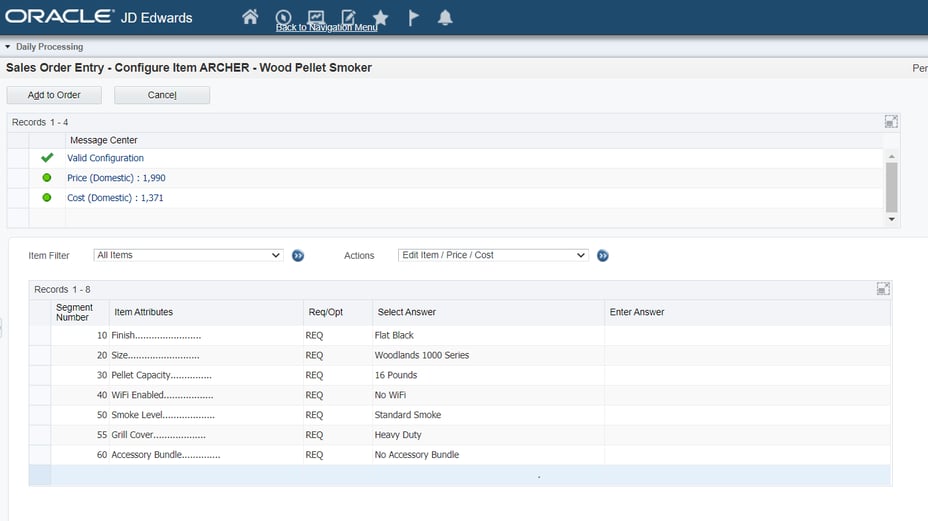

Another thing to notice is that this information changes (as promised) when selections change. See what happens when I change the Grill Cover selection to Heavy Duty:

Did you notice that both the Price and Cost increased?

What about option compatibility and validation?

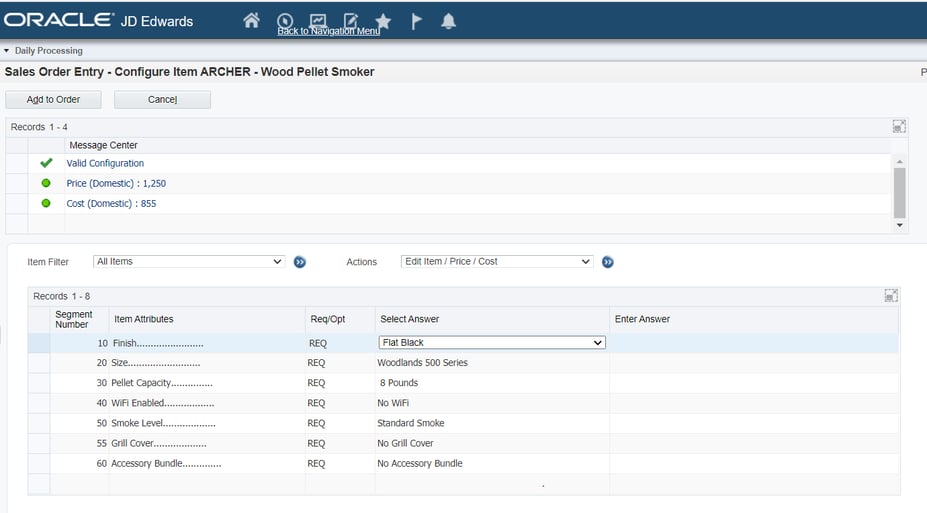

Okay, let us change down to the 500 Series Pellet Grill Smoker and see what happens:

Not only did the Cost and Price go down, but the 500 Series was automatically set to the 8 Pound selection for Pellet Capacity.

If the user tries to override the selection to make a larger capacity, the system won’t let them (because there’s a rule that either your engineering department and/or marketing department has determined is only allowable for the 500 Series). Honestly, the CSR should already know this. I mean, how long have they been doing this? Well, if they just started today, maybe they do not know, which makes me glad there is a Configurator that will not let them hose up an order. See what I did there?

So, we have seen Order Entry and we know that the system already knows the price, cost, and parts. Because the system calculates all this information up front based on the rules, and the Work Order will be created and already include all the parts and routing and any other instructions or calculations necessary to build the product. Lots of time and waste and errors are cut out of the process.

If done correctly, everyone benefits, which should make everyone happy and on the road to success!

CONTACT US TODAY

FOR MORE INFORMATION ON GSI'S JD EDWARDS SERVICES